Have you ever seen an embroidery design that looked flawless on your computer screen but turned into a puckered, uneven mess once stitched on fabric? That usually happens when one key element is missing: proper underlay stitching. These hidden stitches are often overlooked, yet they form the true foundation of every embroidery design. Without the right underlay, even the most beautiful artwork can lose its shape, texture, and professional finish once it hits the machine.

In embroidery digitizing, underlay stitches act like the unseen structure that holds everything together. They stabilize the fabric, smooth out surfaces, prevent puckering, and prepare the area for the top stitches to sit perfectly. Each type of underlay serves a purpose, and professional digitizers choose them carefully based on the fabric type, stitch density, and design complexity.

By the end of this blog, you will understand what underlay stitches really are, the different kinds used in embroidery, why they are so important for quality results, and why hiring professional embroidery digitizing services can make the difference between an average design and a masterpiece.

What Are Underlay Stitches?

The Hidden Foundation of Every Design

Underlay stitches form the base layer of embroidery. They are the first stitches the machine sews before the visible ones appear. These stitches stay hidden underneath the top thread, but they play a vital role in giving the design structure, stability, and smoothness. While the top stitches create the artwork you see, the underlay ensures everything stays in place, neat, and professional.

Like a Building’s Foundation or Primer Coat

You can think of underlay stitches as the foundation of a building or the primer coat before painting. Just as a house needs a strong base to stand firm, embroidery needs solid underlay stitches to maintain shape and prevent distortion. Similarly, the way primer helps paint spread evenly, underlay stitches help top threads sit flat and smooth instead of sinking into the fabric.

Digitizers Choose the Right Pattern for Every Design

Professional digitizers use embroidery software such as Wilcom Embroidery Studio or Ricoma Chroma to select and customize underlay types. They decide which pattern, center run, zigzag, edge run, or tatami, best supports the design. The choice depends on factors like fabric type , stitch density, and design complexity.

Invisible but Extremely Important

Even though you cannot see underlay stitches in the finished embroidery, they determine how clean, stable, and durable the final result looks. Without proper underlay, stitches may shift, pucker, or lose shape. With the right one, your embroidery looks professional, lasts longer, and keeps its quality even after many washes.

The Main Functions of Underlay Stitches

Underlay stitches may be invisible, but they perform several key functions that directly affect how your embroidery looks and feels. Each layer of underlay plays a role in stabilizing the design, enhancing its appearance, and improving its durability. Let’s look at the main functions that make underlay stitches so essential in embroidery digitizing.

a. Stabilizing the Fabric

The first and most important job of underlay stitches is to stabilize the fabric before the top stitches are added. They hold the fabric firmly in place, preventing it from puckering, stretching, or shifting during embroidery. This is especially important for stretchy materials like T-shirts, sweatshirts, and hats, which tend to move easily under the needle. A proper underlay ensures a smooth surface so the top stitches land exactly where they should.

b. Lifting the Top Stitches

Underlay stitches help lift and support the top stitches, adding height, dimension, and clarity to the design. This is crucial for satin stitches and 3D puff embroidery, where depth and definition make the artwork stand out. By slightly raising the top layer, underlays create a crisp, professional look that sets high-quality embroidery apart from amateur work.

c. Reducing Pull Compensation Issues

When the machine stitches at high speed, threads can tighten and pull the fabric inward. Underlay stitches reduce pull compensation issues by spreading tension evenly across the design. This helps each section maintain its proper shape and size, especially in detailed lettering or small designs where distortion is more noticeable.

d. Enhancing Thread Coverage and Smoothness

A good underlay acts as a base layer that fills in the gaps under the top stitches. It prevents the fabric’s color or texture from showing through, resulting in a cleaner, more vibrant finish. This function is vital when working with thin fabrics or light-colored threads that need an extra layer of coverage to look solid and smooth.

e. Strengthening Durability

Underlay stitches also contribute to the long-term durability of embroidery. They create a strong foundation that helps the design withstand repeated washing, stretching, and daily wear. Without a proper underlay, the top stitches may loosen or break over time. With it, the embroidery maintains its shape, shine, and structure for years.

Common Types of Underlay Stitches

| Underlay Type | Description | Best For | Purpose / Benefit |

|---|---|---|---|

| Center Run Underlay | A straight line of stitches running through the center of narrow satin areas. | Small text, fine details, thin satin columns. | Provides light stabilization without adding bulk. |

| Edge Run Underlay | Stitches run along the inner edge of the design outline. | Lettering, borders, and clean edges in satin designs. | Prevents fraying, creates crisp outlines, and sharp edges. |

| Zigzag Underlay | Zigzag stitch pattern that covers a wider area under the top stitches. | Thick satin areas, 3D puff embroidery, raised designs. | Adds loft, smoothness, and strong support. |

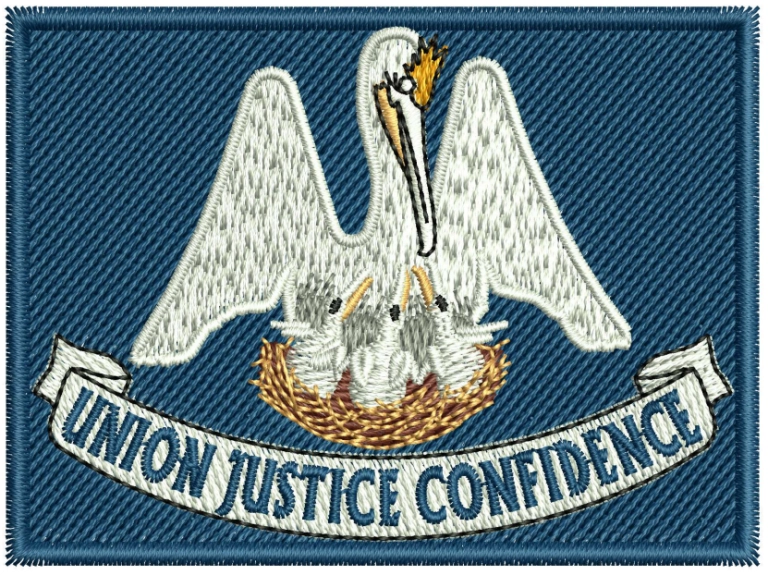

| Tatami (Fill) Underlay | A light fill pattern used under large areas of fill stitching. | Jacket backs, patches, large logos, complex designs. | Stabilizes big areas and ensures smooth, even coverage. |

| Combination Underlay | A mix of two or more underlay types such as edge run plus zigzag. | Dense or multi-layer designs requiring high precision. | Provides extra stability, smoothness, and flexibility. |

Not all underlay stitches are the same. Each type serves a specific purpose depending on the fabric, design, and stitch type. Professional digitizers choose the right combination to achieve clean, durable, and visually appealing results. Below are the most common types of underlay stitches used in embroidery digitizing.

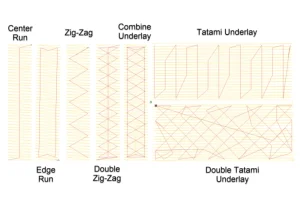

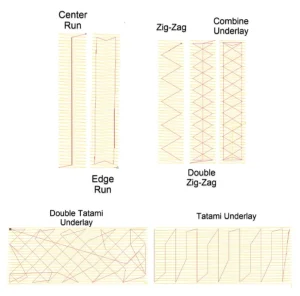

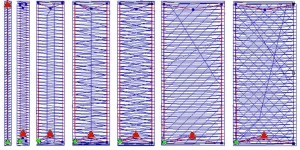

a. Center Run Underlay

The center run underlay is the simplest and lightest form of underlay stitching. It runs as a straight line through the center of narrow satin areas to stabilize the design and prevent distortion. This type is perfect for small text, thin borders, or fine satin details where too many stitches could cause bulk. Although minimal, it provides just enough structure for the top stitches to lay evenly.

b. Edge Run Underlay

An edge run underlay follows the outline of the design, running along the inner edges of satin stitches. It helps create clean, sharp borders and prevents fraying or distortion at the edges. This type is commonly used in logos, lettering, and fine outlines where precision and definition are important. The edge run forms a perfect path for the top stitches to rest on, keeping the design crisp and professional-looking.

c. Zigzag Underlay

The zigzag underlay adds both loft and smoothness to the design. It covers a wider area under the top stitches, making it ideal for thicker satin columns or 3D puff embroidery. The zigzag pattern lifts the top stitches slightly, adding dimension and fullness to the embroidery. It also helps even out textured fabrics and improves coverage.

d. Tatami or Fill Underlay

A tatami (or fill) underlay is used under large filled areas or complex designs. It creates a consistent base that stabilizes the entire section and prevents uneven stitching. This underlay type is perfect for jacket backs, patches, or large logos where smooth coverage and strength are essential. It evens out the surface, ensuring that the top fill stitches look solid and uniform.

e. Combination Underlays

Professional digitizers often use combination underlays, layering different types for the best results. For example, combining an edge run with a zigzag underlay gives both strong borders and raised support for satin stitches. This approach provides an ideal balance between stability, smoothness, and flexibility, ensuring that even complex designs stitch out flawlessly.

Why Underlay Quality Can Make or Break a Design

Poor Underlay Leads to Visible Problems

The quality of underlay stitching can decide whether your embroidery looks professional or falls short. When underlay is poorly digitized, it often causes puckering, uneven stitch density, thread breaks, and distorted outlines. Even a beautiful logo can look messy if the underlay is weak or missing. Without a proper foundation, the top stitches cannot hold their shape or stay flat on the fabric, leading to inconsistent results and wasted material.

Automatic Settings Are Not Always Reliable

Many digitizers rely on automatic underlay settings in embroidery software, assuming the program can do the job perfectly. However, embroidery involves many real-world variables that software cannot always predict. Fabric stretch, stitch direction, thread type, and machine speed all affect how stitches behave. For instance, a soft cotton shirt and a structured hat require completely different underlay approaches. Using one automatic setting for both can result in poor stitching and instability.

Manual Adjustments Make the Difference

Professional digitizers know that every design needs a custom approach. They manually adjust underlay settings based on each fabric type, stitch area, and design complexity. They may change the stitch length, angle, and density to achieve a perfect balance between strength and flexibility. This hands-on technique ensures the embroidery runs smoothly, maintains shape, and produces crisp results.

Quality Underlay Defines True Craftsmanship

A strong, well-planned underlay is what separates a beginner’s work from expert-level embroidery. When handled by skilled digitizers, underlay becomes the invisible hero behind every flawless stitch-out, ensuring that every design looks clean, professional, and long-lasting.

Why Hiring Professional Embroidery Digitizing Services Matters

High-quality embroidery begins with expert digitizing. While anyone can load a design into software and click “auto-digitize,” true professionals understand that embroidery is a blend of art, science, and experience. Every detail, from fabric type to underlay structure, affects the final result. Here’s why hiring professional embroidery digitizing services is essential for flawless, production-ready results.

a. Expertise and Experience

Professional digitizers have the skill and experience to understand how different fabrics like cotton, polyester, fleece, and caps react to tension and stitching. They know exactly when to use multi-layer underlays for thick or stretchy fabrics and where to reduce stitches for lighter materials to avoid stiffness or distortion. Their expertise ensures the design looks perfect, regardless of where it’s stitched, on a T-shirt, hoodie, or structured hat.

b. Use of Premium Software and Testing

Professional companies like Digitizing Buddy use Wilcom Embroidery Studio E4, one of the most advanced embroidery software programs available. This allows them to optimize stitch flow, density, and underlay settings with precision. Before delivering the final file, experts test stitch-outs to ensure clean outlines, smooth fills, and perfect thread balance across different fabrics.

c. Time and Cost Efficiency

Poorly digitized designs can waste thread, machine time, and even garments. Fixing errors during production costs more than doing it right from the start. Professionally digitized files eliminate these issues, saving both time and money while ensuring smooth, error-free machine runs.

d. Consistency Across Orders

When designs are digitized professionally, they stitch consistently on every machine and every fabric. This guarantees that your brand logo or design looks identical across multiple batches, no matter the order size or production location.

Final Thoughts

Quick Underlay Stitch Quiz!

1. What is the main purpose of underlay stitches?

A) To make the design colorful

B) To stabilize the fabric and support top stitches

Underlay stitches are the hidden foundation of every embroidery design. They keep stitches stable, smooth, and long-lasting. Without proper underlay, designs can pucker or lose shape, but with expert digitizing, they look clean, sharp, and professional.

Professional digitizers know how to plan underlays, balance density, and control tension to save both time and fabric while ensuring perfect stitch-outs every time.

Ready to get your logo digitized perfectly? Visit Digitizing Buddy, where prices start at just $10, with free unlimited edits and rush delivery in as little as 2 hours. Get your instant free quote today and experience flawless embroidery results.